A weld stud is a type of fastener that forms a permanent connection with base materials (metal plates, components) through welding processes (such as arc welding, capacitor discharge welding). Its core function is to create an "integrated threaded connection point" on the surface of the base material, replacing traditional drilling and tapping processes. Its characteristics revolve around three core aspects: "efficient connection", "structural strength", and "scenario adaptability", which can be detailed from five dimensions: structural design, welding performance, mechanical properties, material & scenario adaptability, and limitations.

The structural design of a weld stud must simultaneously meet the requirements of "welding firmness" and "subsequent threaded connection". Its biggest difference from ordinary bolts and studs lies in the special treatment of the "welding end", with specific features as follows:

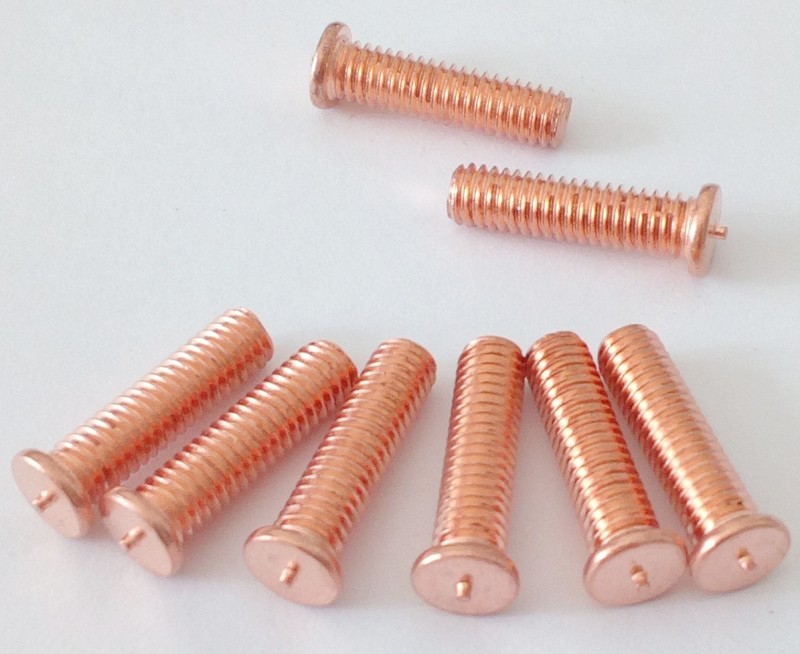

The weld stud is cylindrical in overall shape and divided into two upper and lower sections:

-

Welding end (lower end): Most models are designed with a "flat head" or "chamfered round head". Some high-end weld studs are pressed with "welding grooves" or "positioning bumps" on the welding end—grooves can store the welding molten pool to ensure uniform weld penetration during welding; positioning bumps are used to quickly align the welding position on the base material and avoid deviation. The welding end of some weld studs (such as shear studs) is also wrapped with a "ceramic ring" (welding protective sleeve) to prevent metal spatter from contaminating the threads during welding.

-

Threaded end (upper end): It has a standard external thread structure (e.g., Metric coarse threads M5-M24, UNC American coarse threads 1/4"-1"). The thread precision is mostly 6g (standard grade), compatible with fasteners such as nuts and washers. The top of the threaded end is often designed as a "hexagon head", "cylindrical head", or "countersunk head" to facilitate subsequent tightening of nuts with a wrench (the countersunk head design is suitable for scenarios requiring a flat surface).

The ratio of the "welding end length" to the "threaded end length" of a weld stud must match the welding process: For example, the welding end length of an arc-welded stud is usually 1-1.5 times its diameter (to ensure weld penetration), while that of a capacitor discharge welded stud is only 0.5 times its diameter (since capacitor discharge welding has a short heating time and requires controlled welding range). The overall total length generally ranges from 10mm to 100mm, and the diameter ranges from 5mm to 24mm, meeting the connection needs from light-weight plates to heavy-duty steel structures.

To improve durability after welding, the surface of weld studs is often pre-treated:

-

Low-carbon steel weld studs: Galvanized (hot-dip galvanizing, electro-galvanizing) or nickel-plated to prevent rust at the joint between the base material and the stud after welding.

-

Stainless steel weld studs: Passivation treatment to enhance surface acid and alkali resistance.

-

Weld studs for high-temperature scenarios (e.g., boilers, pipelines): Coated with high-temperature-resistant coatings (such as ceramic coatings) to avoid high-temperature oxidation.

The core advantage of weld studs lies in the characteristics of "welding connection". Compared with the traditional "drilling + tapping + bolt connection", their welding performance can be summarized in 3 points:

There is no need for drilling or tapping on the base material; the weld stud is directly fused with the base material using welding equipment (e.g., the welding time of a capacitor discharge welded stud is only 0.1-0.5 seconds per piece), significantly reducing processes. For example, when installing the wall of a steel structure workshop, the welding efficiency of weld studs is more than 50% higher than that of traditional bolt connections, making them particularly suitable for mass construction scenarios.

During welding, the weld stud and the base material form a "metallurgical bond" (atomic-level fusion) instead of the "mechanical engagement" of traditional bolts, resulting in better tensile and shear resistance:

-

The tensile strength of low-carbon steel weld studs (e.g., Q235 material) after welding can reach 300-400MPa, far exceeding that of ordinary bolts of the same specification (approximately 240MPa).

-

The shear capacity of shear studs (used for shear resistance in steel structures) can be accurately calculated based on the thickness of the base material and the diameter of the stud, meeting the structural safety requirements in the construction and machinery fields.

Corresponding welding methods can be selected based on the material and thickness of the base material, offering strong compatibility:

-

Arc welding: Suitable for thick base materials (≥8mm steel plates) and large-diameter weld studs (≥M12), such as the connection of beams and columns in heavy-duty steel structures.

-

Capacitor discharge welding: Suitable for thin base materials (1-6mm steel plates) and small-diameter weld studs (≤M10), such as the connection of household appliance casings and automobile bodies.

-

Resistance welding: Suitable for stainless steel and aluminum alloy base materials, avoiding oxide scale during welding, such as in food equipment and medical devices.

The mechanical properties of weld studs are designed around "long-term load-bearing" and "anti-failure", with core characteristics including:

The main materials are mostly high-strength steel (e.g., Q355, 10B21) and stainless steel (304, 316). After quenching and tempering, their hardness can reach HV200-300, making them resistant to deformation when bearing axial tension and lateral shear. Especially in dynamic load scenarios (e.g., mechanical vibration, vehicle jolting), the rigidity of the welded connection can avoid the problem of "bolt loosening", making it more stable than traditional bolt connections.

The fusion line at the welded joint is optimally designed (e.g., smooth transition, no sharp corners) to reduce stress concentration. For example, after 1 million vibration cycles, weld studs on automobile chassis can still maintain more than 90% of their initial strength, far higher than that of traditional bolt connections (approximately 70%), making them suitable for long-term dynamic stress scenarios.

The diameter tolerance and total length tolerance of weld studs strictly comply with standards (e.g., ISO 13918, GB/T 10433). For example, the diameter tolerance is ±0.1mm and the total length tolerance is ±0.2mm, ensuring that the height of the threaded end is consistent after welding. No adjustment is required during subsequent installation of nuts and washers, improving assembly accuracy.

The material of a weld stud must match the base material, service environment (temperature, corrosion degree), and load-bearing requirements. Common materials are as follows:

-

Construction and steel structure sector: Fixing of purlins in steel structure workshops, connection of curtain wall keels (using shear studs to transmit shear force), and connection of floor slabs and steel beams—relying on the high shear strength and fast construction efficiency of weld studs.

-

Automotive and transportation sector: Welding of automobile chassis brackets, fixing of truck compartment guardrails, and connectors for subway car bodies—utilizing their fatigue resistance and lightweight materials (aluminum alloy weld studs).

-

Machinery and equipment sector: Assembly of machine tool casings, fixing of motor bases, and connection of conveyor equipment frames—no drilling required, avoiding damage to the strength of the base material.

-

Special environment sector: Guardrails of offshore platforms, accessories of chemical reactors, and equipment in food production lines—stainless steel/alloy weld studs meet long-term use needs with their corrosion resistance.

-

Household appliance and light industry sector: Washing machine casings, air conditioner brackets, and metal frames of furniture—small-diameter capacitor discharge welded studs improve assembly efficiency and reduce production costs.