A petal nut is a type of fastener with a multi-lobed (petal-like) appearance, centered on the core functions of "enhanced grip" and "adaptive fastening for specific scenarios". Its design builds on the "manual operability" of wing nuts and is further optimized—using a multi-lobed structure to improve flexibility and applicability. Its core characteristics can be detailed from four dimensions: structural design, functional advantages, material & scenario adaptability, and limitations.

The structural core of a petal nut consists of a "main body + multi-lobed wings". Unlike the 2 symmetrical wings of a wing nut, petal nuts typically have 3–6 lobes (4-lobe and 6-lobe designs are most common). All structural features serve the goals of "more stable manual operation" and "adaptation to complex installation environments", with specific characteristics as follows:

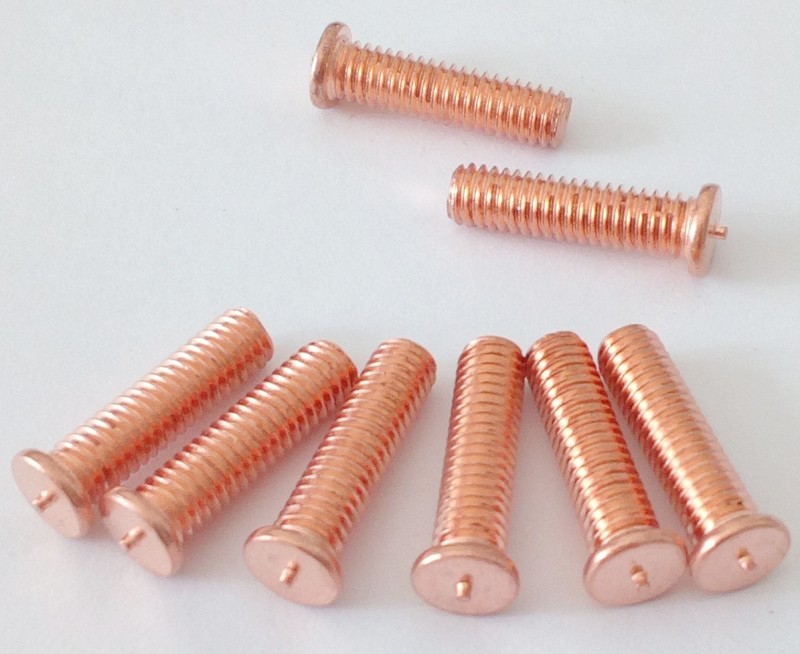

The main body of the nut has an internal thread structure (matching bolts/screws), with 3–6 arc-shaped or trapezoidal "petal wings" evenly distributed around its outer circumference. The wings are usually 3–8mm thick (thicker than those of wing nuts) and 8–35mm long, with 1–3mm gaps between adjacent lobes. The advantages of this design include:

-

Multi-point grip space: Fingers can pinch any two adjacent lobes to twist the nut, eliminating the need for precise alignment with specific positions. This is particularly suitable for scenarios where gloves are worn or hand strength is limited.

-

Force dispersion: The multi-lobed structure ensures that torque during twisting is evenly transmitted to the main body, preventing deformation caused by excessive force on a single wing. Compared to the 2-wing design of wing nuts, petal nuts offer stronger resistance to deformation.

Most internal threads are coarse threads (e.g., Metric M4–M16, UNC 1/4"–5/8"), compatible with most light to medium-duty bolts. The thread precision grade is typically 6H (standard grade), while high-precision 5H threads are used in some industrial scenarios (e.g., mechanical equipment fastening). The bottom of the main body is often designed with an "anti-slip washer groove", which can accommodate rubber washers or metal springs to enhance anti-loosening performance—a structural detail rarely found in wing nuts.

The edges of the petal wings are mostly "rounded" (with a radius of 1–2mm) to avoid scratches from sharp edges. The surface of some models’ wings is pressed with "diagonal patterns" or "dot-shaped protrusions" to increase friction between fingers and the wings, preventing slippage even in oily or humid environments.

The functional design of petal nuts further enhances "stability" and "multi-scenario adaptability" while retaining the "convenience of manual operation" of wing nuts. Its core functional characteristics can be summarized in 4 points:

Compared to the "2-point grip" of wing nuts (with only 2 wings), the "multi-lobed grip" of petal nuts disperses finger pressure, reducing fatigue during prolonged operation. Additionally, the multi-lobed structure allows "wrap-around twisting" with the palm (e.g., 4-lobe nuts can be tightened by pressing the palm against the edge of the lobes to apply force), enabling more efficient torque transmission. The fastening force is approximately 20%–30% higher than that of standard wing nuts (though still lower than that of hex nuts operated with tools).

The small size of the multi-lobed wings (the length of a single lobe is usually shorter than that of wing nut wings) allows operation in "narrow and irregular" spaces—such as areas with crisscrossing pipes inside equipment or hidden connectors in furniture. As long as fingers can reach the gaps between the lobes, twisting is possible, avoiding the "space jamming" issue of wing nuts caused by overly long wings.

-

Anti-loosening: The built-in washer groove can be paired with elastic washers, effectively preventing nut loosening in vibrating environments (e.g., small motors, fan brackets). Compared to wing nuts without anti-loosening designs, petal nuts are more suitable for light-vibration scenarios.

-

Anti-slipping: Patterned surface treatment (e.g., knurling, serrations) on the wings increases friction in wet or oily environments (e.g., kitchen equipment, bathroom accessories), reducing the risk of slippage during operation.

The petal-like shape is more aesthetically pleasing than traditional wing nuts or hex nuts. Some models undergo surface treatments such as brass plating, chrome plating, or anodization (e.g., gold brass petal nuts, silver anodized aluminum nuts). In addition to their fastening function, they can also serve as "exposed connectors" to enhance the overall appearance of products. They are commonly used in scenarios where appearance matters, such as furniture, display racks, and cultural and creative products.

The material selection of petal nuts is based on "scenario requirements", balancing strength, corrosion resistance, and cost. Common materials are as follows:

-

Furniture and home sector: Adjustable parts for wardrobe shelves, hidden connectors for desks, and fastening of bathroom storage racks—utilizing their small size and aesthetics to balance functionality and appearance.

-

Light-duty equipment sector: Brackets for small motors, fan fastening, and connectors for instrument casings—relying on their anti-loosening performance and adaptability to narrow spaces.

-

Decoration and cultural & creative sector: Display racks, handicrafts, and exposed parts of custom furniture—enhancing decorative effects through brass or chrome-plated materials.

-

Humid/lightly corrosive sectors: Kitchen hangers, outdoor flower racks, and aquarium equipment—stainless steel materials meet long-term use needs with their corrosion resistance.

-

Electrical insulation sector: Terminal blocks of low-voltage distribution boxes and fastening of insulating brackets—nylon materials prevent electrical conduction risks with their insulation properties.